Polycrystalline diamond (PCD) die material is made by connecting non-oriented diamond crystals together. The synthetic mass is sintered under very high pressure and temperature in the presence of bonded metal catalysts.

Polycrystalline diamond (PCD) combines hardness, wear resistance, strength, toughness and high thermal conductivity. These unique characteristics make it a high performance material customized in many materials drawings. It is also suitable for many other applications, combining precision and wear resistance.

Polycrystalline diamond is used to make our diamond dies, either as a PCD blank itself (self supporting), or as a PCD blank with a carbide ring (tungsten carbide die supporting). A heat stable blank (without a metal-bonded catalyst) can also be used at high temperatures or without electrical conduction.

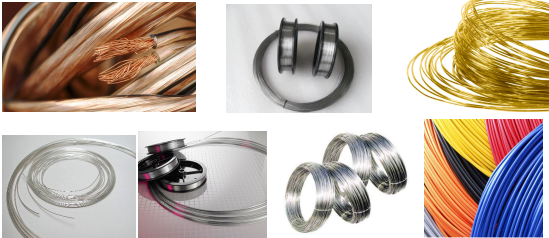

PCD dies are ideal for long-time production and drawing of wear-resistant wire because they are more durable than TC, SSCD and ND dies. Polycrystalline diamond die has various sizes, and there are tungsten carbide supported and self-supported configuration to choose from. PCD mold provides uniform hardness in all directions and increases wear resistance.

Advantage:

1.Durability (more durable than TC and SSCD / nd moulds)

2.Suitable for long-time production and operation

3.Suitable for high abrasive wire rod

4.Even if the die is seriously worn, the wire rod remains round

5.It can be customized for alloy wire

6.Customized for wire requirements (select high quality wire surface when necessary)