.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

| TYPE | DIE SIZE (mm) | STANDARD TOLERANCE (um) | STANDARD CASES | |

| A | B | |||

| ND DIES | <0.04 | 0.5 | 25 | 5 |

| 0.04-0.07 | 0.5 | 25 | 5 | |

| 0.08-0.19 | 1 | 25 | 8 | |

| 0.2-0.39 | 1 | 25 | 8 | |

| 0.4-0.59 | 1 | 25 | 10 | |

| 0.60-0.10 | 2 | 25 | 10 | |

| >1.0 | 3 | 30 | 15 | |

| PCD DIES | D6 | 0.10-0.15 | 25 | 7 |

| D12 | 0.10-0.80 | 30 | 15 | |

| D15 | 0.50-1.50 | 30 | 15 | |

| D18 | 1.00-2.30 | 30 | 15 | |

| D21 | 1.60-3.40 | 30 | 15 | |

| D24 | 2.60-4.60 | 42 | 20 | |

| D27 | 3.00-5.80 | 55 | 24 | |

| D30 | 4.00-11.20 | 55 | 24 | |

| D33 | 6.00-12.50 | 60 | 28 | |

| D36 | 8.00-13.50 | 70 | 35 | |

| D | 12.00-22.00 | 70 | 35 | |

| D | 20.00-32.00 | 85 | 40 | |

|

Wire |

Hard Wire |

Soft Wire |

|||

|

Regular Standrad |

Stainless steel |

Copper-clad steel |

Tungsten, tantalum |

Copper wire |

Aluminum wire |

|

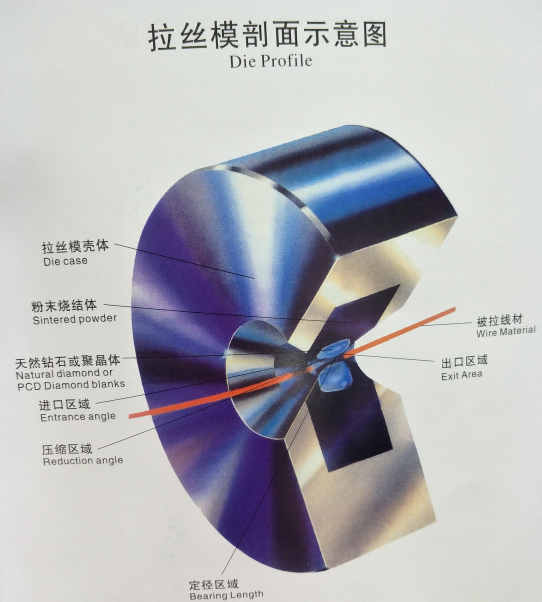

Antry Angle |

80° |

80° |

80° |

80° |

80° |

|

Lubrication Angle |

35° |

35° |

35° |

35° |

35° |

|

Reduction Angle |

14°±2° |

14°±2° |

12°±2° |

16°±2° |

18°±2° |

|

Bearing Length |

0.2-0.5D |

0.2-0.6D |

0.2-0.8D |

0.2-0.5D |

0.2-0.5D |

|

Relief Angle |

25°±2° |

25°±2° |

25°±2° |

25°±2° |

25°±2° |

|

Exit Angle |

60° |

60° |

60° |

60° |

60° |