.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

|

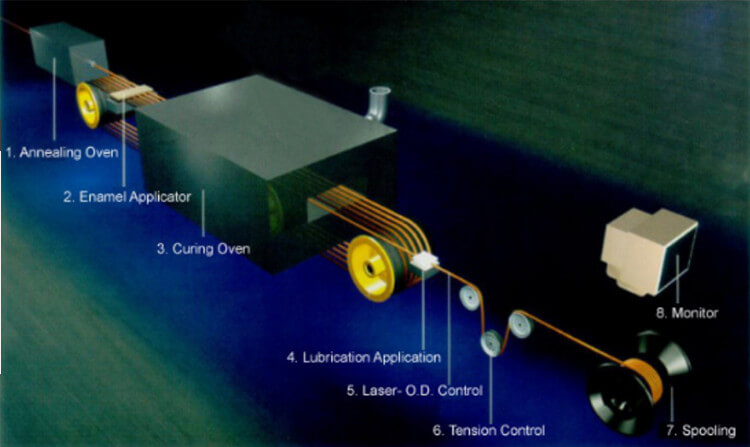

Production Process of Enameled Wire |

||

| 1 |

Annealing Oven |

The bare wire is annealed to achieve necessary softness of copper |

| 2 |

Enamel Applicator |

The enamel is applied in many single layers by the applicator (up to 30) to ensure the good adhesion of the enamel to the copper conductor and to make sure to get a good insulation properties. |

| 3 |

Curing Oven |

In the oven solvents are driven out of the enamel by heat |

| 4 |

Lubrication Application |

Lubrication is for the finished enamel surface to obtain good slidability |

| 5 |

Laser O.D. Control |

The laser will continuously controlled the outer diameter |

| 6 |

Tension Control |

Control the winding tension closely |

| 7 |

Spooling |

The wire is evenly spooled on supply spool with consistent tension |

| 8 |

Monitor |

Continuous production data to operator provided by the Monitor |